Analysis of Causes and Solutions for Condensation of Doors and Windows

In the past, the problem of condensation of doors, windows and curtain walls, which often occurred in cold areas, slowly invaded the whole country due to extreme climate and the popularity of scientific and technological housing. News reports of consumer complaints caused by condensation problems continue to appear in various regions, and the condensation problem has attracted increasing attention. There are many reasons for condensation of doors, windows and curtain walls. Design, production, installation and material problems may cause condensation. What are the specific reasons for condensation and how to avoid it are introduced as follows:

I. N causes of condensation of doors and windows

(I) Installation problems:

1. There is no insulation around the door and window openings

If there is no insulation around the door and window openings, the insulation of the whole building will not continue and the building insulation system will be affected. In architectural design, the thermal insulation requirements of the external envelope should be considered, and thermal insulation measures should be taken around the door and window openings, especially in severe cold areas, the lack of thermal insulation is very easy to form cold bridges, resulting in condensation of walls and window frames.

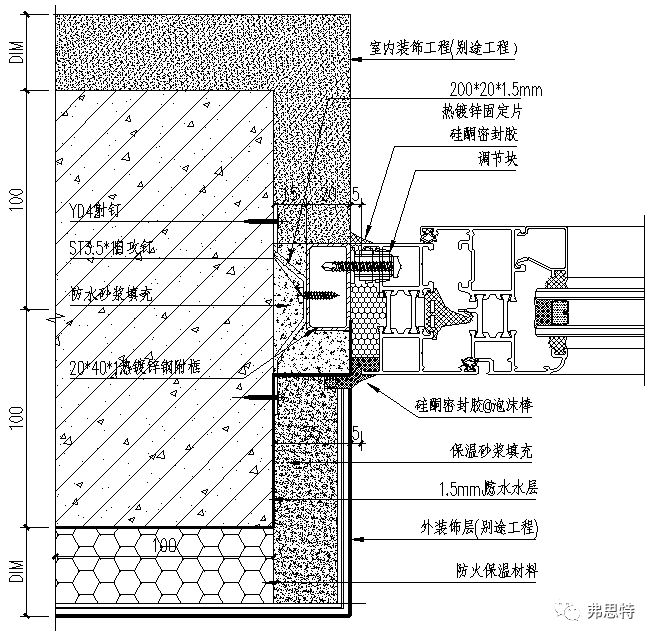

2. Contact between aluminum alloy profile and steel auxiliary frame (structure)

Door and window installation is divided into dry installation and wet installation. In wet installation, non-standard openings or incorrect construction will lead to too small or even no gap between the window frame and the wall, resulting in direct contact between the window frame and the wall, resulting in cold bridge phenomenon. In dry installation, if the gap between the steel auxiliary frame and the window frame is too small or the gap is not qualified, it will also cause direct contact between the steel auxiliary frame and the aluminum alloy door and window frame, or the auxiliary frame is exposed, forming a cold bridge, causing condensation on the window frame and wall at the installation position.

3. Hardware installation is not in place

When the door and window sashes are closed, due to the inadequate installation of hardware, there are gaps between the frames and sashes, and the air tightness of the whole window is poor, which is easy to cause condensation in extreme weather. There is a simple test method for air tightness: put a piece of A4 paper between the frame and sash, and then close the sash completely. If A4 paper can be easily pulled out, it means that the air tightness of the window is very poor.

▲ Simple air tightness measurement method

4.Glass cushion block assembly does not meet the requirements

The length of the glass cushion block shall not be less than 50mm, the thickness shall be more than 5mm, and the width shall not be less than the nominal thickness of the glass, preferably 1 ~ 2mm more than the glass. If the glass cushion block is missing or the specification is too small, the glass will be in direct contact with the window frame, resulting in cold bridge and glass condensation.

▲ Correct selection and assembly of glass cushion block

5. Glass installation and gluing are not qualified

If there is not enough clearance between the glass and the profile, the glass will be in direct contact with the outer profile, resulting in condensation. The space between glass and profile is generally sealed by gluing or adhesive tape, and the thickness of gluing and adhesive tape is determined according to the thickness of glass. At present, the gluing thickness of conventionally used glass is required to be 5mm. The sealant shall be applied smoothly without clearance, especially at the corner. Missing drilling or pores may cause condensation in the later stage. (For incorrect practice)

6.Unqualified assembly accuracy and rubber strip assembly

The assembly accuracy of the profile shall be in strict accordance with the requirements of the specification. The size of the adhesive tape and the profile shall be matched without damage or shortage. The corner of the adhesive tape shall be bonded with special EPDM glue. It is recommended to select the integrated adhesive tape to ensure the sealing of the whole window. Condensation will occur when the temperature difference between indoor and outdoor is large at the position where the assembly accuracy and rubber strip assembly are problematic.

7.The drain hole cover is not installed

In extreme weather, if the drainage hole cover is not installed or the drainage path is not reasonably set, the cold and hot air will enter the profile, which is quite different from the indoor temperature, and it is easy to cause condensation.

(II) Design issues:

1. Indoor humidity calculation and selection of science and technology residential buildings

In the condensation design, the indoor humidity of 60% is generally chosen for the technology residence. The higher the humidity, the higher the requirement for the selection of the whole window material. In the conventional design, the selection of indoor temperature is often neglected, resulting in the phenomenon of large surface condensation in winter. The following figure shows the influence of different humidity on condensation design under the same profile and glass configuration in Tianjin climate environment (profile and glass configuration meet the energy-saving requirements of conventional projects):

▲ The figure above shows the conventional default humidity of 30%, and the result shows no condensation.

▲ The figure above shows the condensation at the position of some profiles with indoor humidity of 40%.

▲ The figure above shows that the indoor humidity is 50%, and condensation occurs at all profile positions.

▲ The picture above shows that the indoor humidity is 60% and all moisture is condensed.

Note: The indoor humidity that the human body feels comfortable is 40% ~ 50%.

2. The fresh air system causes a large amount of space flow around the window frame, and the local temperature difference between indoor and outdoor is particularly large.

If the saturation of water in the airflow formed by the fresh air system is too large, it is easy to cause condensation of doors and windows when it comes into contact with glass with low temperature. The distance between the air outlet and the doors and windows shall be considered in the architectural design, and the air supply outlet shall not directly face the doors and windows.

3. The condensation design does not meet the requirements

Condensation calculation formula:

During project design, condensation calculation shall be carried out according to local indoor and outdoor differences, indoor humidity design requirements of the project and other parameters, and the calculation results must meet the requirements.

(III) Material quality problems

1. Insulating glass lamination is of poor quality

▲ Photo of glass condensation

During the production of insulating glass, two layers of sealant shall be applied. The first layer is applied with butyl rubber, and the second layer is applied with polysulfide rubber (or silicone structural sealant). These two layers of sealant are related to the quality of the insulating glass. If the two layers of sealant are not applied tightly in the process of laminating, the moisture in the air will enter the spacer layer, which will increase the water content of the insulating glass spacer layer and cause glass condensation. When the glass is installed, the construction unit shall provide the glass re-inspection report including the heat transfer coefficient, visible light transmittance, shading coefficient and dew point of the insulating glass for inspection.

▲ Correct glass laminating method

2.The material of the heat insulation strip does not meet the requirements

According to the requirements of the specification, the material of the thermal insulation strip shall be polyamide 66 + 25% glass fiber, and other materials such as PVC shall not be used. The unqualified thermal insulation material will directly affect the energy saving and structural strength of the whole window, resulting in condensation and material deformation.

3. The cavity of the profile is large, and convection is for in the cavity

For the profile system with a large cavity, the cavity can be filled to avoid convection.

II. How to avoid condensation

1.Before the installation of doors and windows, it is necessary to check the accuracy of the opening and confirm that the opening meets the installation conditions before construction. The correct installation method should be adopted during installation. The following installation forms are widely used at present, as shown in the figure below:

2.Doors and windows shall be installed with functional frames

As shown in the isotherm distribution above, the heat transfer coefficient of the energy-saving auxiliary frame is lower than that of the steel auxiliary frame, which can avoid the formation of a cold bridge at the installation position. The size of the energy-saving attached frame is more, which can meet the needs of various profile series, and the steel is a non-renewable resource. Therefore, from the perspective of environmental protection, energy saving, application and later replacement and maintenance, the energy-saving accessory frame has more advantages.

3. Strictly control the quality of various materials, such as heat insulation strips, glass, rubber strips, etc.

Materials are the guarantee of the performance of the whole window, and the materials of each project must meet the requirements to ensure that the doors and windows do not condense.

4. The condensation design of the whole window meets the requirements of the maximum temperature difference and indoor humidity in the area.

During the design, energy saving and condensation calculation shall be carried out according to the actual needs of the project. It is necessary to take into account the extreme climate, such as the extreme low temperature in Shanghai last year, and the condensation of doors and windows in many projects, which should be calculated in advance in the design to avoid.

5. Consider all kinds of situations, such as fresh air system, science and technology residence, etc.

Comprehensively consider the particularity of the project, communicate with other influential disciplines according to the requirements of the project, modify the condensation boundary conditions that cannot be changed, and carry out experimental testing.

6. The glass shall be provided with warm edge strips or filled with thermal insulation materials in the profile cavity.

The glass is filled with warm edge strips and thermal insulation materials in the profile cavity, which has a positive effect on energy saving and condensation of the whole window. According to the calculation of the current common series, these two methods can reduce the heat transfer coefficient of the whole window by 01~0.2W/(㎡•K), which is also very helpful to avoid condensation around the profile and glass.

When designing doors and windows, condensation design shall be carried out in strict accordance with the maximum temperature difference and indoor humidity of the building location. Before installation on the wall, it can simulate the real environment and carry out experiments. If condensation occurs, the temperature range of doors and windows can be known through the infrared temperature tester. In case of condensation problem, check the cause of condensation through the condensation position first. If the cause cannot be checked, break down and check, and rectify the detected problem in time.